Centerless vs. Cylindrical Grinding

Leave a CommentGrinding is a machining process that utilizes an abrasive grinding wheel to remove material. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. While there are many grinding methods available, two of the most used for cylindrical parts are centerless grinding and cylindrical grinding. These processes have some similarities, but they also have distinct characteristics that make them suitable for different manufacturing applications.

The following blog post discusses the similarities and differences between centerless and cylindrical grinding to help readers understand which one will best suit their project needs.

What Is Centerless Grinding?

Centerless grinding works best at machining the outside diameter of simple, cylindrical parts. It involves feeding a workpiece between a stationary grinding wheel rotating at high speeds and a slower regulating wheel which spins and drives the part, in the case of through-feeding. An angled workblade secured between the grinding and regulating wheels serves as a resting place for the workpiece.

Since the workpiece is not affixed during centerless grinding operations, centers are not required on the part, nor is a chuck needed to hold and rotate it. Parts with uniform outside diameters can be quickly through-fed. Using simple axial stops, shafts with journals can be plunge-ground. Both methods produce parts with excellent roundness held to ultra-precise diameter specifications.

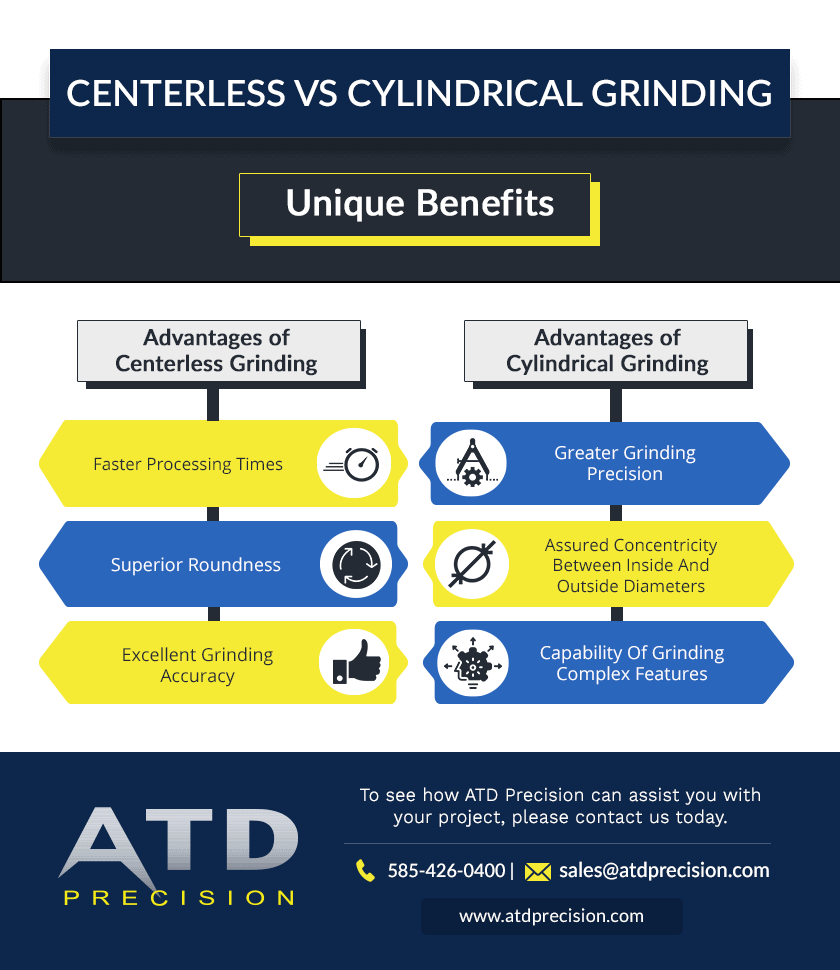

Some of the advantages that centerless grinding offers over other methods include:

- Faster processing times

- Superior roundness

- Excellent grinding accuracy

What Is Cylindrical Grinding?

Cylindrical grinding uses a headstock that is comprised of a chuck, or a center with a driver, to hold and rotate the workpiece. The part is typically supported by a tailstock with another center that, along with the headstock, move together axially, or side-to-side, on a machine table. The grinding wheel engages and cuts the part by moving radially, or in-and out, perpendicular to the workpiece.

By securing the workpiece and being able to move it axially, cylindrical grinding is much more versatile, allowing for multiple diameters, complex shapes, and angles to be ground. Moreover, the use of centers ensures that all diameters ground about the central axis of rotation are concentric with each other as well as with any other internal diameters that are concentric or “true” with the centers. It is an inherently precise and stable machining process.

Some of the advantages that cylindrical grinding offers over other methods include:

- Greater grinding precision

- Assured concentricity between inside and outside diameters

- Capability of grinding complex features

Applications of Centerless Grinding and Cylindrical Grinding

Both centerless grinding and cylindrical grinding are effective component machining methods. However, they are suitable for different parts and products due to the differences in their equipment and workpiece setup requirements.

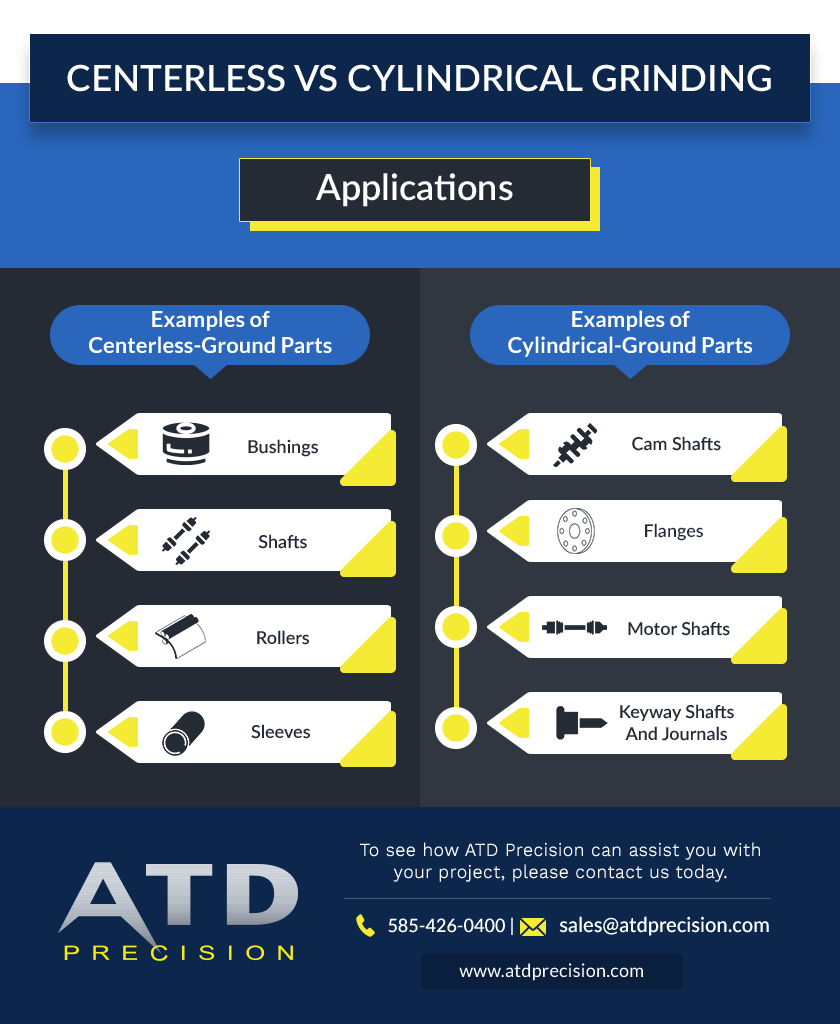

Some examples of centerless-ground parts:

Some examples of centerless-ground parts:

- Pins

- Bushings

- Shafts

- Rollers

- Sleeves

Some examples of cylindrical-ground parts:

- Cam shafts

- Flanges

- Machine arbors

- keyway shafts and journals

- Sun gears

Learn More About Centerless and Cylindrical Grinding From ATD Precision

Want more information on the similarities and differences between centerless grinding and cylindrical grinding? Ask the experts at ATD Precision! Having extensive experience providing centerless and cylindrical grinding services to customers with highly technical challenges, we can answer or address any questions or concerns you may have about the processes.

To learn about our precision grinding capabilities and how we can assist you with your next grinding project, check out our precision grinding capabilities or request a quote today.